eCabinet Systems Software - Features

|

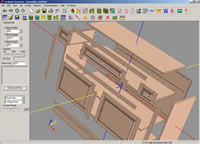

CABINET FURNITURE DESIGN

Starting with a standard base, upper or corner cabinet, new designs are developed by modifying size, construction and settings. Doors, drawers, shelves, face frames, hardware carvings and moldings can be added/changed. A Door/Drawer Editor can define virtually any door. A Part Editor allows you to modify individual parts to create structures or designs not supported by primary functions. Multiple cabinets can be combined into Assemblies. Cabinets and Assemblies are saved in libraries.

|

In the work area, cabinets are displayed as 3D objects that can be moved, rotated, exploded and zoomed and represent an exact image of the current design. Individual parts can be hidden, wireframed or made transparent allowing careful inspection of joinery and fit. Color, texture and grain direction can be adjusted for each part. Doors and drawer fronts can be grouped to preserve grain pattern through multiple parts during nesting.

CUSTOM LAYOUT

Room structures are developed including walls, openings for doors, windows, etc. System supports various ceiling heights, tapered walls and cathedral ceilings. Approx 6,000 wallpaper patterns are available for walls, various floor coverings are supplied plus any color can be used for walls/floors. Custom jpegs can be used for wall/floor covering including stretching a single real world jpeg over a floor or wall for highly realistic reproductions. Using Display Cubes and applied images, design items such as fireplaces, benches, rugs, stairs, as well as virtually any appliance can be accurately reproduced. Various lighting can be added.

Cabinets and assemblies can be added and positioned in the room. As they are added, the system estimates cost, calculates selling price for the job and tracks items that must be purchased. A Presentation View develops photorealistic views of the layout including shadows and reflections.

Cabinet material and appearance, door and drawer design and decorative hardware can be modified in the layout and the system calculates differences in cost as this occurs. A cabinet or Assembly can be taken to the Cabinet/Assembly Editor and modified.

BATCH PROCESSING

Should a room layout not be necessary, jobs can be processed by simply adding cabinets and assemblies to a batch at which time full manufacturing support and cost estimating are available.

MANUFACTURING SUPPORT

At any time, in either the Cabinet/Assembly Editor or the Custom Layout, you can generate a Cut List, Buy List and Cost Sheet for a single cabinet or assembly or any combination of cabinets and assemblies. The job can be nested, at which time it provides overview nest diagrams of the entire job, dimensioned diagrams of each sheet nest and dimensioned drawings of each individual part. The system can also create a CNC output file that can be sent to a Thermwood CNC control to produce the nested parts as well as any custom profile in the job. If a tool does not exist for the custom profile, the control creates a modeling program to model the profile using standard tools. CNC programs to produce carvings used in the job are rented directly through the Thermwood CNC control.

COST ESTIMATING

A cost estimating system tracks job costs and, based on user parameters, outputs material, labor and overhead costs as well as expected profit and selling price. Two different approaches to calculating these costs are available. Costs can be displayed along the bottom of the screen and are available in the Cost Sheet.

LINE DRAWINGS

A Drawing Editor imports cabinets, assemblies, walls or entire rooms and allows easy dimensioning. The system supports drawing in any plane as well as isometric and exploded diagrams.

DISPLAY PART EDITOR

In this area, 3D objects in the .STL file format can be colored and textured creating highly realistic display objects that are saved in the .HSF format where they can be added to cabinets or layouts.

CONTOUR MANAGER

This CAD like area is used to develop profiles that can be turned into tools and applied to parts in the Part Editor.

HARDWARE HOLE EDITOR

This area is used to create a hole pattern or machining pattern that is associated with a drawer slide, hinge or KD/RTA fitting. Each time the item is used, the appropriate hole pattern is added to the cabinet.

PROPOSAL WRITER

Once configured for a shop, this area quickly creates a professional sales presentation for a job. The output can be imported into Microsoft Word for further refinement and modification.